This month's newsletter focuses on Research Theme 3 - Support the decision maker.

IN THE SPOTLIGHT #

Congratulations to Ryan Loxton on the recently-launched Curtin Centre for Optimisation and Decision Science. This new centre focuses on developing efficient mathematical techniques for the optimisation and control of complex systems. It closely aligned with CTMTDS, particularly the optimisation research in Theme 3. Some of the new centre projects include optimising force design with Defence Science and Technology Group, optimising aeration control for grain silos with Industrial Automation Group, and optimal process control with Lynas Rare Earths.

Congratulations to Melinda Hodkiewicz on being selected as a finalist in the Women in AI Awards 2022. Melinda was nominated as a finalist for AI in Manufacturing. The winners will be announced at an awards ceremony in Melbourne on 31 March 2022.

Team News #

We welcome Ponpot Jartnillaphand back to start his PhD with Theme 3, supervised by Dr Elham Mardaneh , Dr Mojtaba Heydar and Dr Hoa Bui.

Kyle Fethers joined the Centre to complete his Honours with Research Theme 3 . He started this month on a placement project with Roy Hill. This placement will inform Kyle's Honours project, and we will share more about his research later this year.

Theme 3 - Support the Decision Maker #

Research Theme 3 is dedicated to finding the right balance between the costs of preventative maintenance and the disruptions caused by on-site failures. The effects of maintenance planning on long-term productivity are not well-studied as it requires an extensive, systematic exploration of all options. Nevertheless, the potential benefits are enormous.

Researchers have continued working closely with industry partners to develop algorithms to optimise maintenance scheduling, decreasing downtime and associated costs. The focus in 2021 was on building industry understanding of the algorithms and to enhance research relationships between industry partners and researchers.

Researchers in Theme 3 include Prof Ryan Loxton , A/Prof Mark Reynolds, Dr Elham Mardaneh, Dr Hoa Bui, Dr Mojtaba Heydar, Yingying Yang, Sandy Spiers, Ponpot Jartnillaphand, and Kyle Fethers

Industry Placements #

Sandy Spiers at Alcoa #

Sandy Spiers is undertaking an industry placement project identified by Alcoa that aligns with his PhD on maintenance optimisation for network-connected assets. His research focuses on building and developing mathematical models to improve the maintenance management of critical assets.

Working with Alcoa, Sandy is optimising the maintenance of digester banks, a critical path asset found in the Bayer process. Digesters play a crucial role in the refinery's operation, meaning their maintenance schedule is generally planned well in advance. However, determining a suitable schedule can be challenging due to operational setups, site-wide requirements, and budgetary and risk considerations.

During his time at Kwinana, Sandy has worked alongside the Alcoa Data Science Team and site specialists to build an optimisation tool for digester bank maintenance. After many debugging phases, Sandy has delivered a working tool that can provide operators and schedulers with an optimal digester maintenance schedule that satisfies all desired constraints. The tool provides autonomy to the operators' workflow, quickly adapts to changes in the required schedule, and suggests ways to improve the overall maintenance strategy further. The essential decision metrics are presented in a PowerBI Dashboard that operators, schedulers and managers can use to make important budgetary and strategic decisions.

Industry Placements during COVID restrictions require a lot of flexibility from everyone. When going to the Alcoa refinery in Kwinana became impossible, Sandy worked virtually and Alcoa employees came to Curtin. Sandy Spiers working on industry problems with Noah Lester from Alcoa at Curtin University. Sandy is mentored by Dr Moussa Mansour and supervised by Alcoa engineers and maintenance personnel with expertise in the assets and refinery experience. Sandy has made valuable connections with industry and is building an in-depth knowledge of the maintenance scheduling processes.

Mojtaba Heydar and Hoa Bui at the Nickel West maintenance shutdown #

Mojtaba Heydar and Hoa Bui joined the Nickel West maintenance shutdown in March 2022. Developing a better understanding of the dynamics of the refinery during a shutdown will enable Mojtaba and Hoa to improve their shutdown scheduling tool.

Getting practical experience and identifying the real needs of end-users is one of the most critical parts of building real-world mathematical models. Experience on-site not only provides a pragmatic view on how industry will use the optimisation tools; it also inspires our researchers to use theoretical research to solve real problems.

We thank the Nickel West team for their tremendous support. Hoa and Mojtaba had a great experience and gained valuable knowledge from the shutdown to use in their scheduling tool.

Research Activities #

Optimised activity scheduling for maintenance outages #

Shutdowns provide opportunities to complete essential maintenance activities that are only performed when the equipment is not in production. Due to production requirements, the equipment cannot be turned off for long periods, so minimising the shutdown time is essential. However, there is a clear trade-off between minimising the outage duration and minimising the maintenance costs and resources. Therefore, an optimised shutdown requires planning the maintenance activities and organising resources, tools and parts in advance. This is a significant challenge because the situation often changes on a daily basis, with maintenance priorities shifting and new maintenance activities emerging. For these reasons, having a dynamic tool to help the managers and schedulers quickly generate shutdown schedules under different conditions to assist their decisions is highly desired

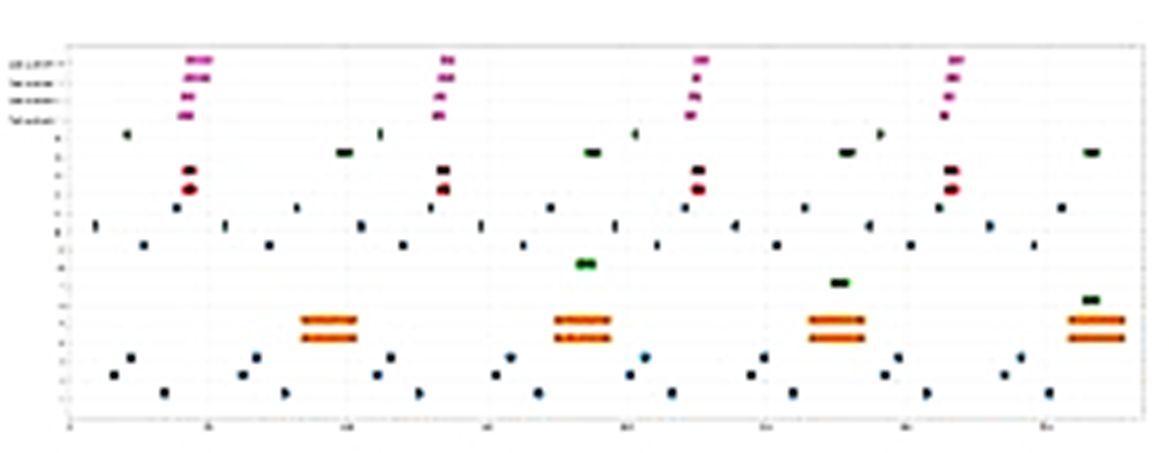

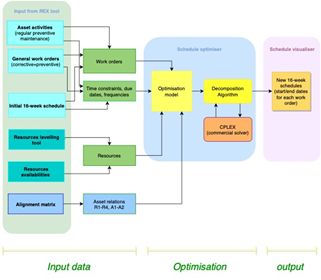

Hoa Bui has developed such a tool through work completed on Nickel West furnace outages. The tool was used during furnace outages in July and August 2021. With software development support from Theme 5 and John Hille, Hoa and Mojtaba are working with Nickel West planning specialist Duncan Bailey to implement this solution in Nickel West systems.

Shutdown timing optimisation #

Yingying Yang has been working with Josh Boath from Roy Hill on a scheduling solution over an extended period. Instead of providing a solution for a short-term, single maintenance operation over a week, Yingying is researching how to stage multiple maintenance operations over a long time horizon, e.g. 2 years or 3 years, where equipment maintenance shutdowns affect production. These shutdowns are interrelated, and two parts of the plant may not be able to be shutdown at the same time. Yingying is focusing on how such interrelated shutdowns can be staged over a two- or three-year time frame.

Optimised maintenance scheduling for inter-connected digester banks #

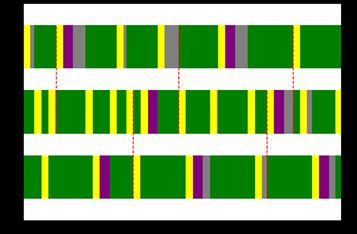

Sandy Spiers has been working with Moussa Mansour Alcoa to optimise the maintenance scheduling for interconnected digester banks at Alcoa. The digester banks have a maintenance frequency where there are constraints around their connections to other parts of the plant. For example, suppose there are valve changes occurring on a particular piece of equipment. In that case, other maintenance operations need to be synchronised with that activity, which will affect production. These interrelationships among assets present a challenging set of constraints when optimising maintenance scheduling.

Rolling horizon continuous maintenance optimisation #

This maintenance work flow above arises out of Hoa Bui's work on Alcoa's 16-week maintenance schedules. How can schedulers optimise a sequence of maintenance activities over that time frame and at the same time avoid clashes and maximise synergies? There are specific activities or outages that cannot occur together. However, other outages can occur together because they share resources or are in the same location in the plant. Hoa's work generalise the 16-week scheduling under such constraints over a rolling horizon on a continuous basis.

Stay tuned for our next issue at the end of April where we will cover: #

- Research Theme 2

- New publications

- Research updates